Conex Boxes are also known as shipping containers and are the cargo containers that allow goods to be stored for transport in trucks, trains, and boats, making intermodal transport possible. They are typically used to transport heavy materials or palletized goods.

This type of shipping term was referred to as Container Express and became to be abbreviated as “ConEx.” Conex became universal and was later used to identify the entire category of shipping containers. Connex is also an accepted spelling and can be referred to as conex box, conex, conex container, connex box, conex boxes.

Conex is also referred to as shipping container, ISO container, conex box, railroad container, intermodal container and certain truck trailers. This industry term refers to the International Standards Organization (ISO), the largest developer of international standards and the organization that developed the standard dimension specifications for steel shipping containers used worldwide.

The design of the ISO standard containers allows for intermodal shipping, which is the movement of containers from one mode of transport to another, like ship, rail, or truck, without the need of having to load and unload, and reload its contents.

Conex Boxes are used to protect transported cargo from shock and bad weather conditions, as well as keep storage products intact. They were first used in the 1950s and were initially developed for the purpose of commercial shipping.

Depending on the type of product that is going to be sent, the Conex box can vary in dimension, structure, material, etc. Characteristics of these shipping containers were later standardized, something that expedited transport without the need to load and unload the merchandise along the way.

There are different types of Conex Boxes for different types of transportation:

Common types include:

· Dry Storage Conex Boxes

· Refrigerated Conex Boxes

· Open Top Conex Boxes

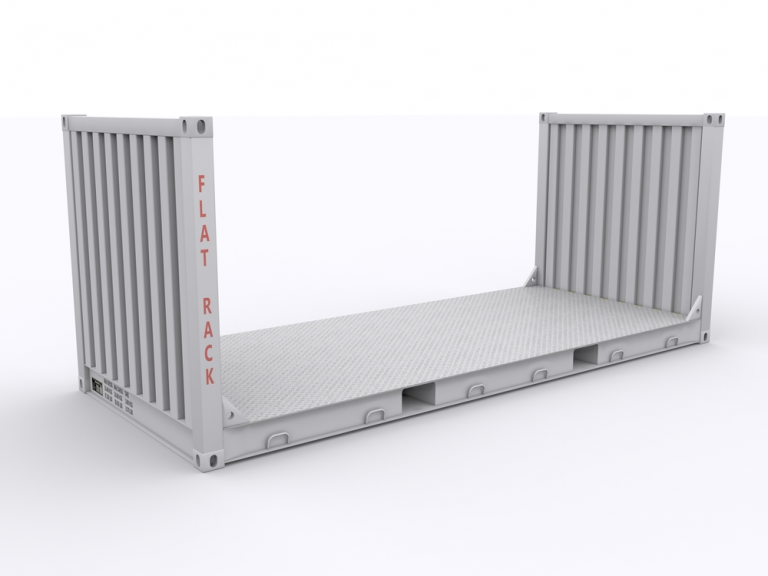

· Flat Rack Conex Boxes

· Open Side Conex Boxes

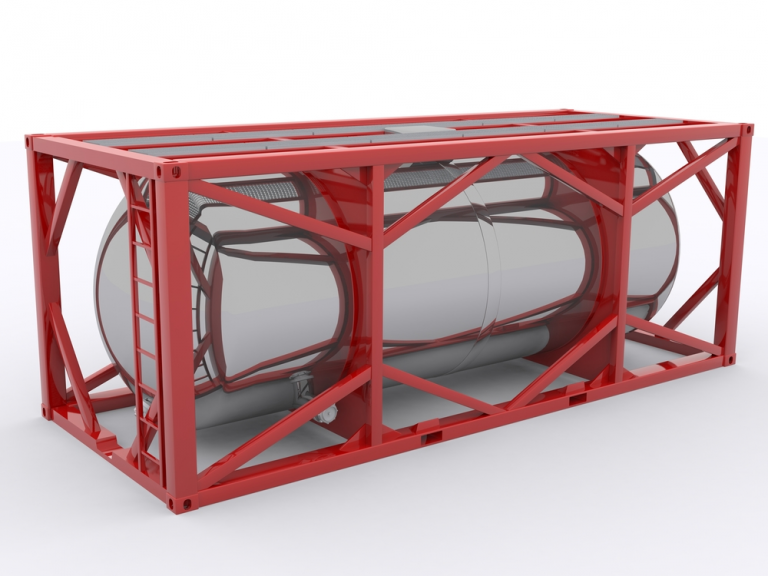

· Tank Conex Boxes

· Ventilated Conex Boxes

For more information about the differences, please visit the link at the end of this video.

Now we are going to run through the essential parts of a conex box.

For a door to work, you need hinges. Pins hold the conex box’s hinges together through a barrel. In certain cases when doors are difficult to open, hinge pins and blades may be seized due to corrosion.

Each door is fitted with 2 to 4 vertical lock rods to enable opening, closing and locking of the doors.

The door handle rotates the lockbar to initiate the door opening process by forcing the cams out of their keepers. Each door handle has a door locking handle retainer that slides over the door handle when in locked position.

At the end of each lock rod is a cam welded in place which engages with knuckles, also known as cam keepers. The action of engaging the cams to the keepers forms an anti-racking function. In certain cases, often unfortunately too many, contents of the conex box may have shifted causing conex box doors and lockrods to warp.

When opening a conex box, start with the right hand door first. Swivel the handles, engage the cams and keepers, and twist both door handles. Closing the doors is just a reverse of this process.

The lock box is a steel box welded to the right hand door which overlaps a staple welded to the left hand door. A padlock, normally CISA type 285 66 can then be attached inside the lock box through the staple and is then protected from direct attack, hindering attempts to gain entry to the conex container.

ISO markings and a consolidated data plate allow worldwide intermodal transport and are updated as necessary.

Take note that customs authorities in some countries may also have their own container seal regulations as part of their national security.

Rubber gaskets are fitted to the container doors during the manufacturing process and prevent water ingress. Door gaskets are designed to present two or more fins against the structure or adjacent door. These are generally flexible but when the gasket is damaged, they may become stiff thus jamming the door closed, or preventing it from being closed.

Conex boxes often take a beating, traveling around the world, being exposed to freezing conditions and rust due to seawater or when the frost has melted.

During the cold season, and in freezing parts of the world, our conex box tool can benefit the opening and closing of frozen conex box doors and hard to open or rusted containers.

Injuries often occur as a result of personnel trying to open and close difficult container doors, and often are the result of inappropriate techniques being used to open them.

To aid in opening and closing conex box doors, we introduce OPNBar.

Our conex box tool can simplify the opening/closing of conex boxes in freezing or wet conditions. It’s versatility can also help to open/close rusted or worn out containers, thump tires, and release tractor from trailer.

Our 3 in 1 conex box tool gives you the best bang for your buck in addition to the safety and savings our tool provides to trucking companies and their safety departments, along with insurance companies, reduced workman’s comp claims.

http://shippingcontainertool.com

Trucking Company Safety – Reduce Injury / Workmans Comp Risk

Did you know that cargo and insurance companies lose billions a year due to operator injury? We introduce 3 Trucker Tools in 1! A conex box safety hand leverage tool, designed for opening and closing trucking and conex boxes, a Tire Thumper, and 5th Wheel Pull Hook, designed with the safety of the driver, operator, and worker foremost in mind.

For more information, visit: http://www.shippingcontainertool.com

Like us on Facebook:

https://www.facebook.com/shippingcontainersafety

Follow us on Instagram:

https://www.instagram.com/opnbar/

Shipping Container Safety International

10053 Whittwood Dr, Suite 11284 Whittier, CA 90603 USA | OPNBAR

657-667-6227